Best Android apps for Electronic and Electrical Engineers

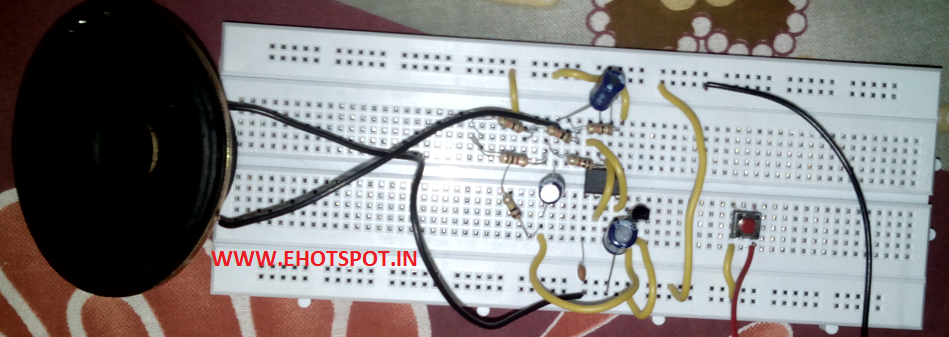

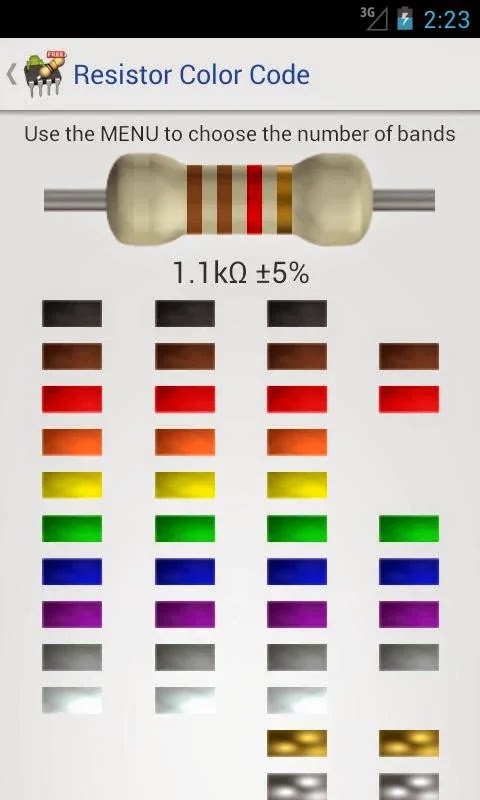

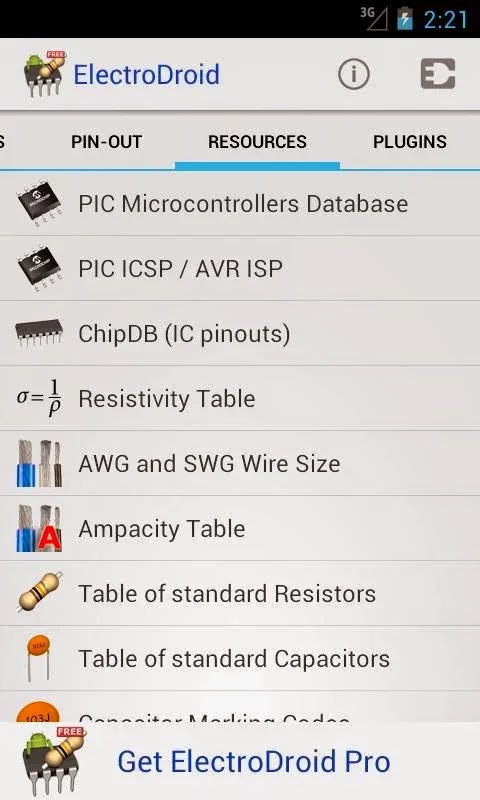

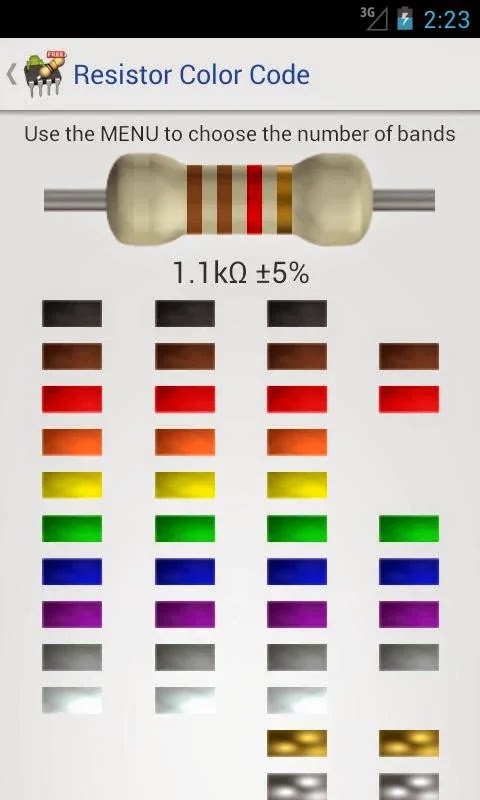

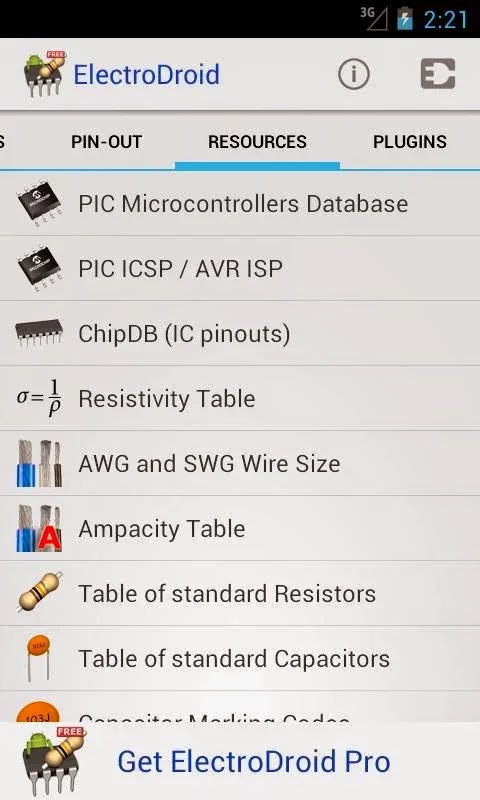

1.Electrodroid

ElectroDroid is a simple and powerful collection of electronics tools and references.

s.jpg)

sfs.jpg)

Download Electrodroid free

2.Everycircuit

EveryCircuit is not just an eye candy. Under the hood it packs custom-built simulation engine optimized for interactive mobile use, serious numerical methods, and realistic device models. In short, Ohm's law, Kirchhoff's current and voltage laws, nonlinear semiconductor device equations, and all the good stuff is there.

ElectroDroid is a simple and powerful collection of electronics tools and references.

s.jpg)

sfs.jpg)

Download Electrodroid free

2.Everycircuit

EveryCircuit is not just an eye candy. Under the hood it packs custom-built simulation engine optimized for interactive mobile use, serious numerical methods, and realistic device models. In short, Ohm's law, Kirchhoff's current and voltage laws, nonlinear semiconductor device equations, and all the good stuff is there.

Growing library of components gives you freedom to design any analog or digital circuit from a simple voltage divider to transistor-level masterpiece.

Schematic editor features automatic wire routing, and minimalistic user interface. No nonsense, less tapping, more productivity.

3.Engineering Handbook Lite

This is an amazingly useful and handy app for every engineering student. It provides all the concepts of engineering and formulae and can also help in length mathematical calculations.

4.Droid Tesla

is another free app for simulating electronic circuits. This SPICE simulation tool is quiet similar to the app “EveryCircuit” mentioned above in its functionality - means you can build and simulate a circuit. But they both (EveryCircuit and DroidTesla) differ in user interface and features provided.

5.Electronics Tooolkit

is another free app which is a collection of simple tools like resistor color code calculator, series and parallel calculator etc. Almost all those tools are available in ElectroDroid app too, except for a Power Triangle calculator. I have listed this app here as it is free (and I have spent some time to download and test this app in my Galaxy) and you guys can try out, if you have time.More than 10,000 users have tried this application.

6.AllDataSheet app

This app is free version of the Datasheet website Alldatasheet.com. This app is nothing more than a book mark to alldatasheet website’s mobile version. I dont recommend you to download this app as your purpose will be served by visiting Alldatasheet.com from your mobile browser (which will get automatically redirected to mobile version)

7.Logic simulator

Logic Simulator is a powerful tool for simulating logic circuits and testing how different gates can be used in a circuit,

It offers a big workspace and a simple menu system. It is perfect for education on a mobile platform.

To connect nodes you simply click on an output and then click on an input to connect it to.

8.Electronics Calculator

Simple electronics tools & calculators for your DIY projects.

Tools:

- Resistor Color Code (4,5 &6 band)

- Capacitor Conversion Calculator & Table

- Capacitor Code Converter (code to values - vica versa)

- Resistor in Series & Parallel

- Capacitor in Series & Parallel

- Resistor Color Code (4,5 &6 band)

- Capacitor Conversion Calculator & Table

- Capacitor Code Converter (code to values - vica versa)

- Resistor in Series & Parallel

- Capacitor in Series & Parallel